06

Applications

Capillary flow-controlled wicks.

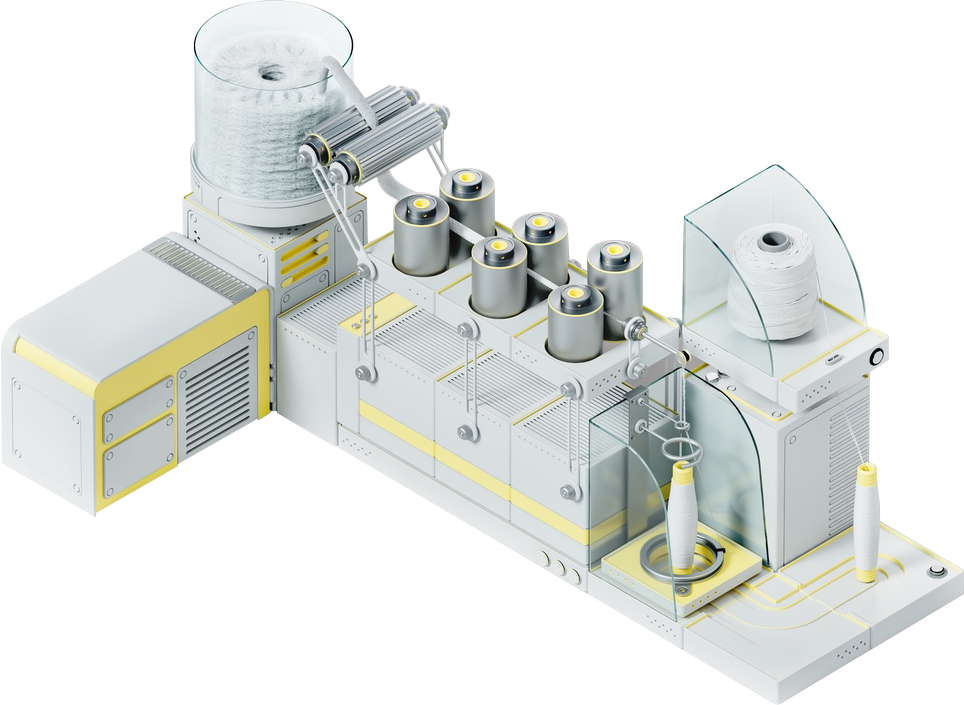

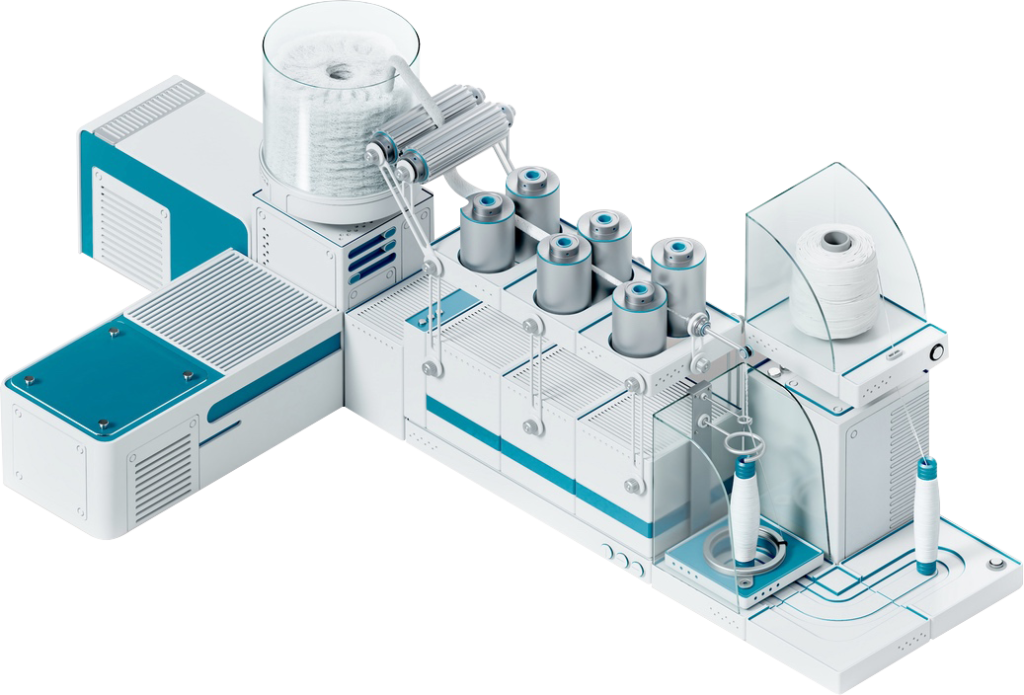

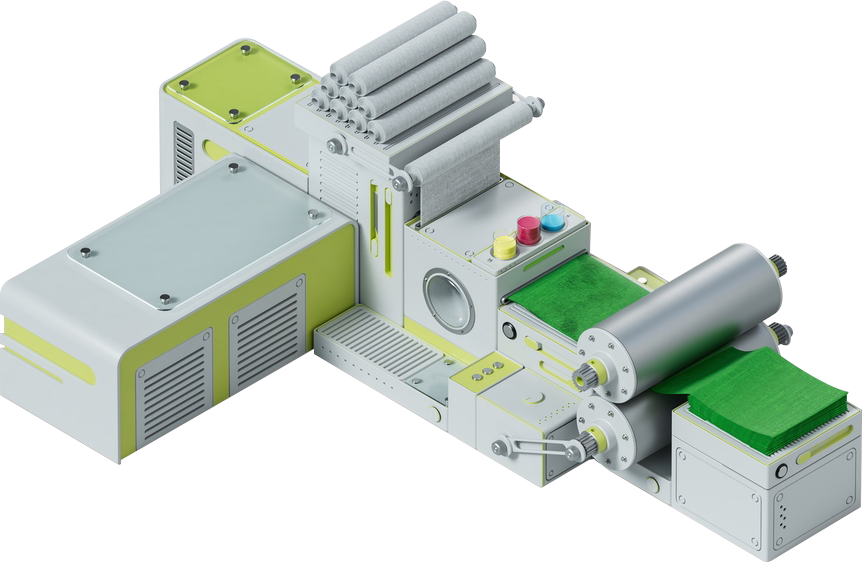

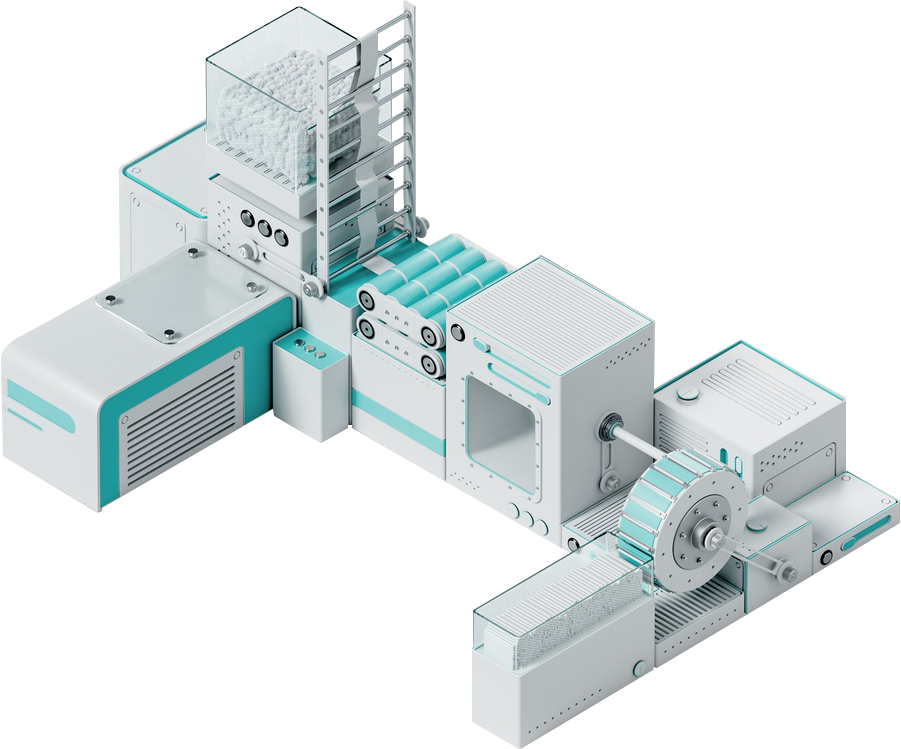

WINDING

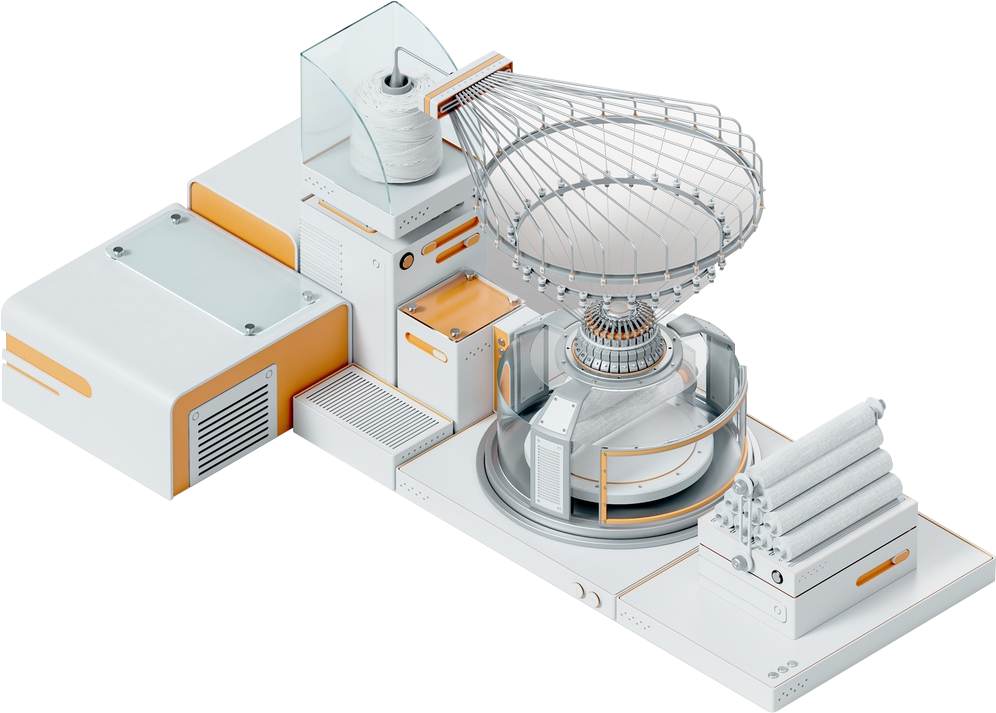

The product is presented to the extruder for the creation of a web.

CUT

The tape is cut into individual filters and subjected to quality control.

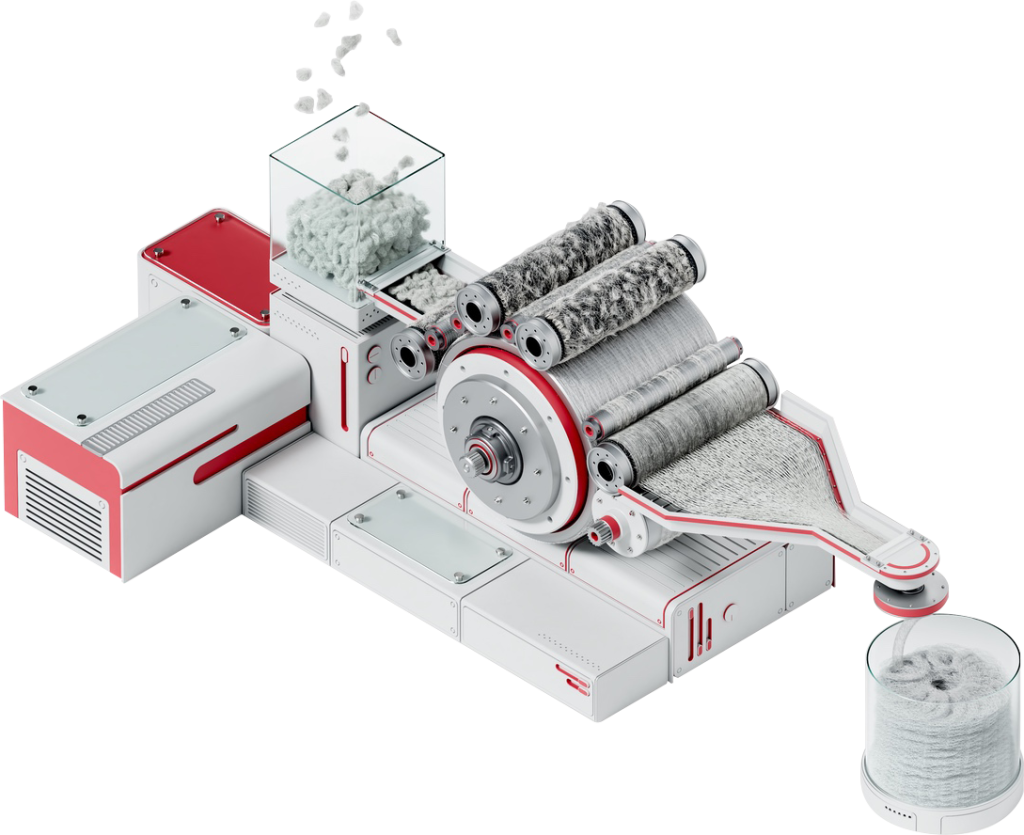

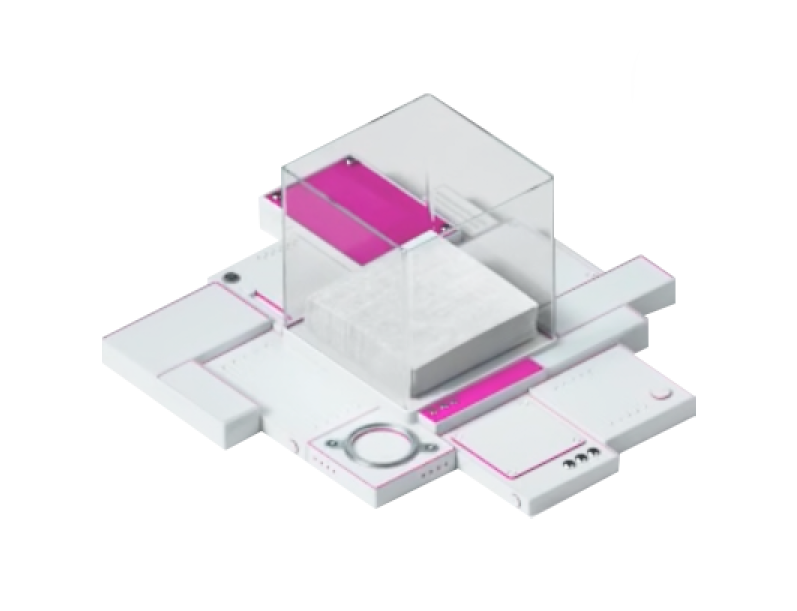

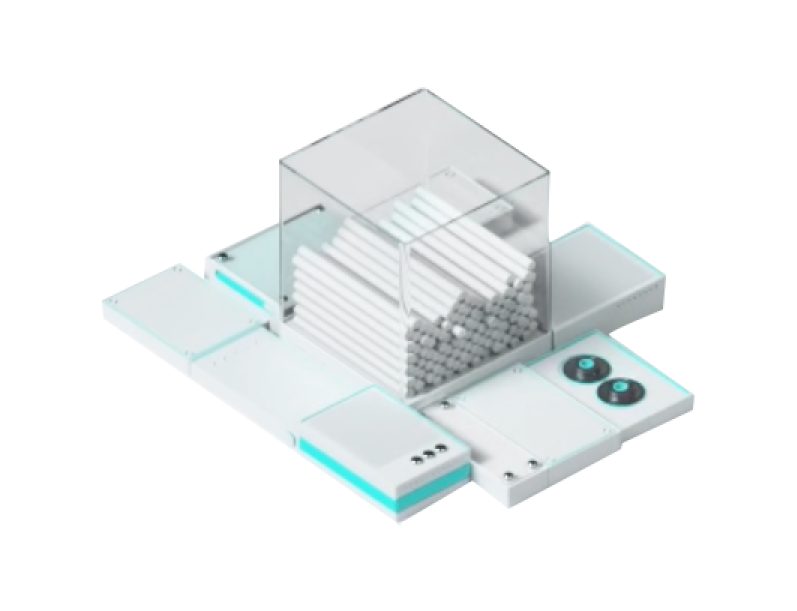

Input

Fiber

OUTPUT

Innovative textile applications such as controlled capillarity filters

In the early 1970s, De Martini, building on its tradition in the textile industry, began its journey of differentiation in the production of controlled capillary filters. Today, we produce and distribute acetate, polyester and polypropylene fibre filters and supply the world’s leading manufacturers of writing instruments, air and home care devices, beauty and cosmetic products and many other special applications.